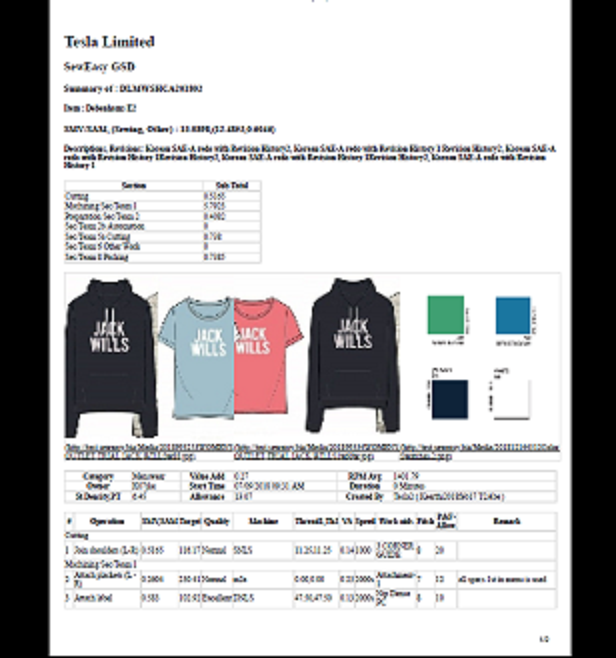

Keerthi Abe of SewEasy Pvt. Ltd. and our Partners specialize in “automating” the industrial engineering (IE, work-study) functions of Ready Made Garment business. Our SewEasy® GSD Garment Sewing Data system is used for measuring the Standard Minute Value (SMV, SAM, SAH), the labour content for Garment Costing. Let our database, your designer’s Sketch, Image, Graded Spec or a sewn Sample initiate the journey into “Open Costing” path and transparent price points to stay ahead of the Value Engineering curve.

Smart Factory Bottleneck Management by SewEasy will draw your attention to critical lapses as and when they occur via email anytime anywhere, freeing up your time for buisness travel and engagements. Digitalisation enables your critical manufacturing operations to raise flags. Enjoy Industry 4.0 Lean, flat benifits now!

Incentivising Workers to motivate earning higher fair Wages, Piece-Rates, Capacity Planning, Loss-Time based Line Balancing for increasing Sewing Efficiency. We specialize in automating SMV calculation for Sourcing, Risk-Management, Sewing-room pre/post cost review and Social & Labour Compliance in supply chain. Benchmark and Up-Skill workers using SewEasy® and implement lean by quick elimination of Muda, Muri and Mura through Kaizen. Innovate sustainable fashion.

SewEasy helps sourcing with open-cost, capacity assurance, leading to improved work-flow in the value stream, resulting in higher productivity and profits. For decades, we empowered sewing teams to guarantee better methods and organic-growth. Change enterprise focus from optimizing separate technologies, assets, and vertical departments to the ‘flow’ of garments through value streams, horizontally across technologies, assets, and departments towards fashion retailers.

Transform a mere wasted motion (ugoki) into value added work (hataraki). Moving about quite a bit does not mean working. To work means to let the process move forward.

Achieve Target-Cost through value engineering and simulation of technical specifications such as Speed, RPM, Stitch Density SPI etc.

SewEasy GSD is acknowledged in research conducted under the auspices of the University of Manchester as one of the leading agencies specialising in predetermined motion time systems.

Walmart/ASDA sourcing switched to SewEasy GSD for quick SMV (SAM) estimation to achieve open costing compliant labour benchmarks in their Lean Program. The Costing Engineers are especially impressed by the speed of estimation using SewEasy GSD Garment Sewing Data and on-line, global access of completed analysis free of charge.

SewEasy GSD licensing, certification and online e-learning management system (LMS) equips IE professionals with essentiol tools for the development of sustainable fashion industry across the globe.

Walmart, ASDA, Debenhams retailers, brand owners, sourcing divisions and leading buying houses as well as compliance oriented manufacturers recommend SewEasy GSD System for raising productivity, performance and profits in order to improve fair wages sustainably.

Innovative, dynamic Asian manufacturers including Hirdaramani, Orient Crafts and Fakir Fashions integrated SewEasy in the supply chain for product development and sampling, gained competitive edge and lucrative returns. Using globally recognized SewEasy GSD (Garment Sewing Data), the industry leaders swiftly realize training and skill development milestones in sewing.

You can create totally new items/styles after a day’s training. We provide item creation as a service to brands and retailers, be it mass, craft or artisan based production environment.

Start with common style database. Innovative 200+ multi-language menu localization is proof of our simplified lean strategy. 中文, 選項, 普通话, tiếng việt, 國語, 臺灣華語, Mga Pilipino, Indonesia, ኢትዮጵያ, हिन्दी, বাংলা/বঙ্গ, پنجابی, Türkçe, español, Росси́йская Федера́ция, தமிழ், සිංහල, Et al.

Sew Easy Pvt. Ltd is number one in implementing modern, professional, simplified and quick Industrial Engineering (IE) systems around the globe, for 25 years.

What is unique about our IE approach is that, SewEasy® GSD Garment Sewing Data system can be commissioned within days to bring harmony to the production and quality teams. Local SMEs and global mega manufacturers benefit alike as seen in testimonials.

We Customize our Solution and boost Factory Production Management System Free of Charge to fix Line Balancing and Absenteeism.

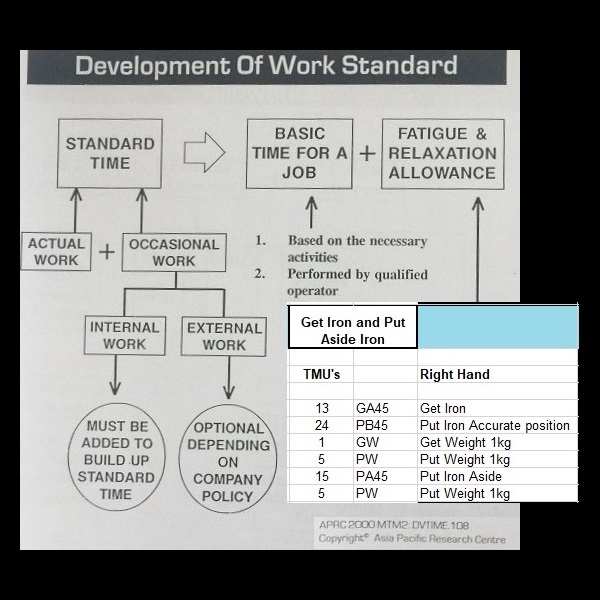

We provide you all the user accounts required for secure main-site work. Our free training up to one (1) year follows, one-week free on-site training and implementation. We boost your IE, Lean journey through Free ERP/PLM integration and re-focus on Efficiency/VA KPIs. 365 days of progress monitoring and continuous focus on developing IE skills, stimulate factory workforce to apply their best effort towards the factory overhead cost reduction. Managing efficiencies of competing teams is easier and longer lasting through incentive systems, Features & Macros. Describe LH, RH with MTM TMUs.

Establish specifications based on the ISO Standard to match manufacturing complexity of new products/buyer opportunities.

ILO’s Introduction to Work-Study, Fourth (revised) edition is complied in its meaning and form by SewEasy GSD System to set International Labour Standards (ILS).

Cloud, web browser based or in your Local Server choice of Scalable SewEasy GSD solution blended with best available Industrial Engineering and Lean Sewing know-how, automates your tedious mathematical work automatically using Common style database, Masters, Styles, Features, Operations and Codes. Such innovative, professionally run factories are valued by leading Brands, Retailers, Sourcing Companies, Buying Offices and ESG investors alike. Lifetime Free Software Upgrading.

See below more: Product Features & Your Benefits..

The SewEasy® GSD (Garment Sewing Data) system would help increase productivity, performance and profits of garment exporters’ through visible, simplified and accurate production planning. On time delivery and right quality are facilitated by standardization. Factory management will be based on produced minutes. Work measurement and performance indicators will govern.

We conduct on-site diagnostic surveys at units or plants. Then evaluate needs which will be followed by skillful lean implementation. Bulk production of knit/woven garments or artisans at export oriented community centers and units are critical to modern responsible retailers. Baskets, Jackets or lingerie the lead times are trimming season after season.

Efficient sewing machine operators, sewing lines and work-cells are built up on “operation” SMV (SAM), line balancing, the skilled supervisors and managers working towards hourly factory goals, that guarantee low absenteeism during style change overs and reduced labour turn over. Referred as Predetermined Time Standards (PTS) and Predetermined Motion Time Standards, Predetermined motion time system (PMTS).

SewEasy GSD is a very powerful Lean solution designed with Toyota Sewing Engineering concepts to suit the buyer as well as the manufacturer to maintain a single communication channel across fashion designer, merchant, production manager and sewing machinist. The largest buying office already switched to Value Engineering with SewEasy GSD, and it is your turn to innovate now.

and explore..

You will focus on key aspects of sewing from day one to achieve targets.

and explore..

We deliver following key training skills.

and explore..

Our specialty is in focusing on following key aspects.

about your needs..

Meet competitive demands, focus on key result areas.

I believe with SewEasy and the Lean factories its a powerful combination…. a solution to change the industry for good.

We have been using SewEasy® since 1995, compares well with any other system, and readily recommend.